How MaxSilo Silage Inoculants Work

Directing Fermentation with Proven Microbial Science.

Silage fermentation is a biological race. As soon as forage is harvested, naturally occurring microbes begin to compete for nutrients. If left uncontrolled, this process often favours undesirable organisms — including clostridia, enterobacteria, and spoilage yeasts — which can degrade protein, consume sugars, and generate unwanted compounds like ammonia and butyric acid. The result is reduced feed value, dry matter (DM) loss, poor aerobic stability, and lower intake potential.

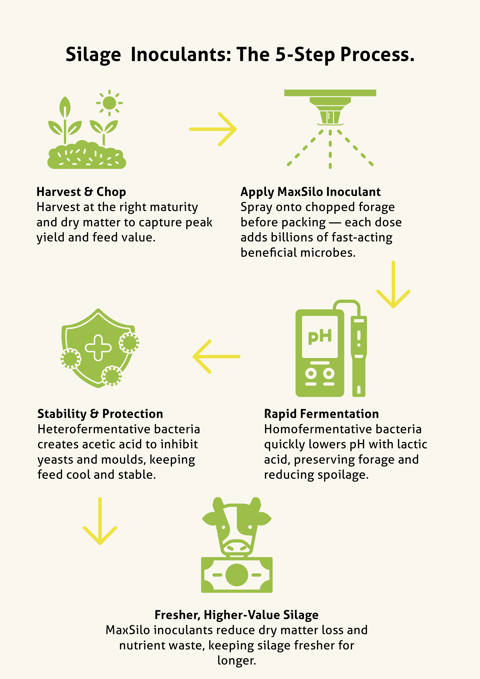

MaxSilo silage inoculants shift the balance in your favour. Using scientifically selected lactic acid bacteria (LAB), each formulation introduces a high concentration of beneficial strains to rapidly acidify the forage, suppress spoilage microbes, and preserve valuable nutrients for your livestock.

Strains Explained

Strains Explained

MaxSilo silage inoculants use carefully selected strains of lactic acid bacteria (LAB) to guide efficient, targeted fermentation. Our homofermentative formulations (MaxSilo Prime and MaxSilo Prime Plus) drive a rapid drop in pH by converting sugars into lactic acid, helping to inhibit spoilage organisms like Clostridium and Listeria, preserve protein, and minimise dry matter losses. In contrast, heterofermentative products (MaxSilo Cool and MaxSilo Cool Plus) also produce acetic acid — a powerful antifungal that protects against heating and spoilage during feed-out. While slower-acting, these strains are essential for silage with higher aerobic risk, such as maize or whole crop cereals.

What Are Microbial Strains — and Why Do They Matter?

In microbiology, a strain refers to a specific genetic variant or subtype of a microbial species. While two bacteria might belong to the same species — for example, Lactobacillus plantarum — different strains within that species can behave very differently in terms of their metabolic activity, stress tolerance, fermentation speed, and effect on silage quality.

For silage inoculants, strain selection is critical. It’s not enough to use just any lactic acid bacteria (LAB) — only certain strains are well-suited to the challenging conditions of silage, such as low oxygen, fluctuating temperatures, and varying forage types.

Why Specific Strains Are Used in MaxSilo

Each strain in a MaxSilo inoculant is chosen for its performance in silage trials, its resistance to environmental stress, and its synergy with other strains in the same formulation. This ensures predictable, efficient fermentation with proven outcomes — whether your goal is nutrient preservation, aerobic stability, or both.

How do Homofermentative and Heterofermentative Lactic Acid Bacteria (LAB) differ?

MaxSilo provides silage inoculant solutions with different functions to cover a range of forage types and ensiling conditions; from more efficient fermentation leading to increased nutrient preservation and spoilage prevention, to reducing yeast and mold and increasing silage aerobic stability.

| Feature | Homofermentative LAB | Heterofermentative LAB |

| Primary Function | Rapid acidification of silage | Enhancing aerobic stability |

| End Products of Fermentation | Lactic acid only | Lactic acid + acetic acid |

| Main Benefit | Quick pH drop to inhibit spoilage microbes | Spoilage suppression during feed-out |

| Key Strains Used | Lactiplantibacillus plantarum, Pediococcus pentosaceus, Lacticaseibacillus paracasei | Lentilactobacillus buchneri, Levilactobacillus brevis |

| Effect on Aerobic Stability | Limited effect | High (due to acetic acid production) |

| Effect on Nutrient Preservation | High (better preservation of sugars and proteins) | Moderate to high |

| Forage Type Examples | General use, hard difficulty to ensile forages (Tropical and temperate grasses, legumes) | General use, easy to moderate difficulty to ensile, silages prone to spoil at feed out (Whole-crop corn, grains) |

Faster Fermentation for Superior Silage Preservation

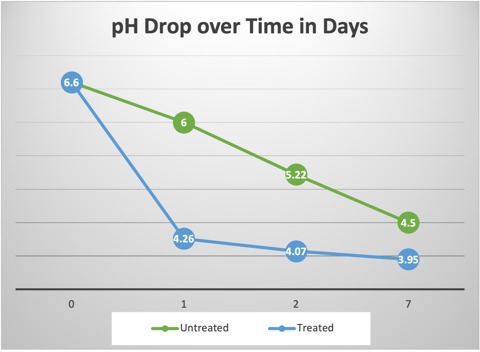

A well-managed fermentation process is essential to preserving the nutritional value of your forage. MaxSilo inoculants promote a rapid and controlled drop in pH, creating an environment that actively inhibits the growth of spoilage organisms such as Listeria monocytogenes and Clostridium species — both of which are unable to proliferate below a pH of 4.5.

By more quickly establishing an acidic, anaerobic environment, our homofermentative bacterial strains outcompete undesirable microbes, reducing the breakdown of valuable nutrients. This minimises energy, protein, and dry matter losses, while also improving silage stability and hygiene.

The outcome is more than just well-preserved silage — it’s improved animal performance, thanks to higher feed quality, better palatability, and more consistent nutrient intake throughout the feeding period.

Multi-Strain Synergy for Rapid, Efficient Fermentation

MaxSilo Prime and Prime Plus combine two complementary bacterial strains in one powerful formulation, each playing a distinct role in driving a fast and stable fermentation:

-

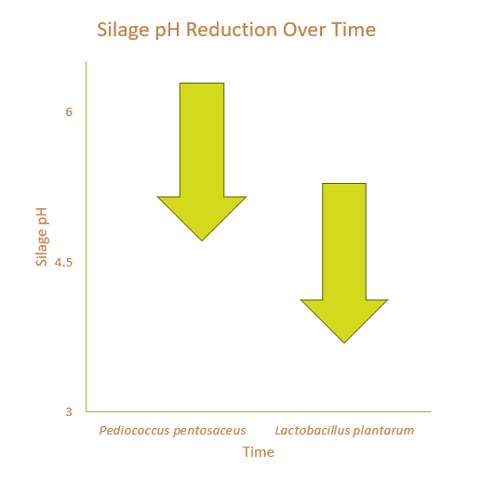

Pediococcus pentosaceus – A robust starter strain that activates quickly at higher pH levels. It thrives in drier forage and aerobic conditions typically present during the early stages of ensiling, ensuring a strong initial fermentation kick-off.

-

Lactiplantibacillus plantarum – A highly efficient strain that completes the fermentation process, rapidly driving pH down to stable levels once anaerobic conditions are established. It ensures full preservation of nutrients and inhibits undesirable microbes.

Synergy in Action

Together, these strains form a synergistic partnership: Pediococcus initiates, Plantarum completes. The result is a faster, more reliable fermentation that minimises nutrient losses, enhances feed stability, and ultimately supports better animal performance.

Protein Preservation: Protecting True Nutritional Value

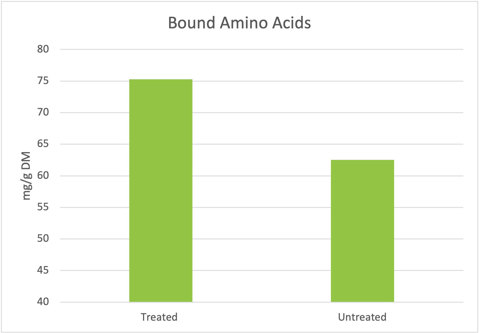

One of the most critical aspects of silage quality is the retention of true protein — amino acids that remain intact and available for absorption by the animal. During poorly controlled fermentation, proteolytic activity from undesirable microbes (such as clostridia and enterobacteria) breaks down proteins into non-protein nitrogen (NPN) compounds like ammonia and amines, which are far less efficiently utilised by ruminants.

MaxSilo inoculants help protect true protein content by rapidly reducing pH, thereby inhibiting the enzymes and microbial populations responsible for proteolysis. In well-treated silage, this results in a 20% increase in bound amino acids, compared to untreated forage.

These amino acids represent true protein — the most valuable form of nitrogen for growth, reproduction, and milk production.

Why True Protein Matters

True Protein vs. Non-Protein Nitrogen (NPN)

While ruminants can recycle some NPN via microbial protein synthesis in the rumen, true protein delivers more efficient and predictable nutrition. It contributes directly to muscle deposition, milk protein synthesis, and reproductive success.

Economic Advantage

Preserving naturally occurring true protein in the silage reduces the need for costly dietary supplements such as soybean meal or rumen-protected amino acids. In today’s volatile feed markets, this translates into significant cost savings per tonne of silage.

Improved Performance

Animals fed silage with higher true protein levels consistently show better feed conversion efficiency, increased daily gain, and higher milk solids output — all of which contribute directly to profitability.

In summary: MaxSilo doesn’t just preserve feed — it preserves the quality of that feed at a molecular level, ensuring more of the original protein reaches the animal in its most usable form.

Ammonia Reduction: Improving Silage Palatability and Intake

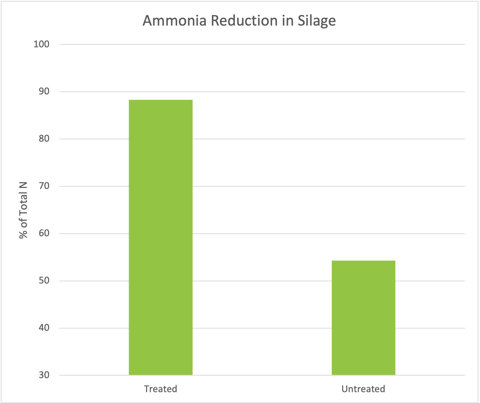

One of the clear markers of protein degradation in silage is the presence of ammonia-N — a byproduct of proteolysis caused by clostridia, enterobacteria, and plant enzymes during poorly managed fermentation.

High levels of ammonia not only indicate nutrient loss but also contribute to reduced feed palatability, negatively affecting voluntary intake.

MaxSilo inoculants help reduce ammonia production by accelerating the pH drop and suppressing undesirable microbial activity early in the ensiling process. This fast acidification preserves protein structure and limits the breakdown of amino acids into ammonia and other non-protein nitrogen compounds.

In controlled trials, MaxSilo-treated silages showed a 38% reduction in ammonia content compared to untreated controls — a clear indication of more stable, efficient fermentation.

Why Ammonia Matters

Lower Ammonia = Less Protein Waste

Ammonia forms when proteins are deaminated during microbial spoilage. High ammonia levels mean more true protein has been lost, reducing the nutritional value of the silage.

Improved Palatability and Dry Matter Intake

Ammonia has a sharp, pungent odour and bitter taste, both of which can suppress voluntary intake, particularly in high-performance dairy cows or finishing animals. Lower ammonia levels enhance the smell and flavour of the silage, encouraging higher dry matter intake (DMI).

Better Feed Efficiency and Performance

Higher intake of better-quality silage translates directly into improved animal productivity — whether in terms of milk yield, growth rates, or reproductive outcomes.

In essence: by reducing ammonia levels, MaxSilo not only protects silage quality but also helps animals eat more — and perform better.

Bringing Science to the Silage Clamp

From rapid pH reduction to long-lasting aerobic stability, MaxSilo forage inoculants use precision-selected microbial strains to control fermentation, protect nutrients, and maximise the feed value of every crop. Whether you're ensiling grass, maize, or whole crop cereals, the science behind each MaxSilo formulation ensures predictable results — less spoilage, better intake, and improved animal performance.

Ready to choose the right inoculant for your operation?

Explore the MaxSilo Product Range ➜